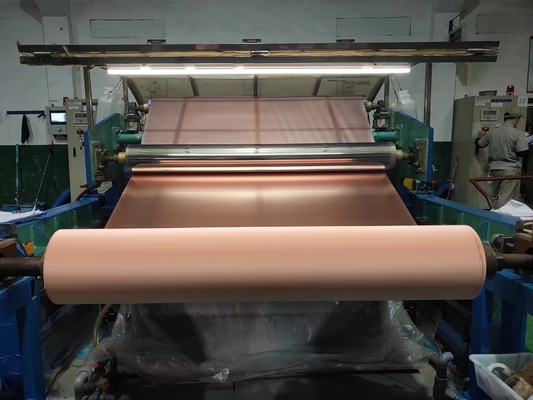

25um HD electrolytic ED copper foil for Polyimide board

Overview:

Rang of Thickness: 25micron

Range of Width: 1380 mm

Range of Length: 500-5000 M

Available ID: 76 mm,152 mm

Purity:99.8%

Features of high ductility ED copper foil:

1. Good etch ability

2. Excellent adhesion to etching resist

Classify :

The ED copper foils for PCB can be divided into below parts:

(STD-E)- standard electrodeposited copper foil

(HD-E)-high ductility electrodeposited copper foil

(HTE-E)-high temperature elongation electrodeposited copper foil

(LP-E)-low profile electrodeposited copper foil

(VLP-E)-very low profile electrodeposited copper foil

difference between CA copper foil and ED copper foil

1. Process: rolled copper foil (Rolling process),ED copper foil (Electrodeposition process)

2. Density: rolled copper foil higher density, the surface is relatively smooth, conducive to the production of printed circuit board after the rapid transmission of the signal, so high-frequency high-speed transmission, fine lines printed circuit board also used some calendering copper Foil.

3. Surface treatment width:rolled copper foil be limited by Surface treatment widest effective width of 520mm.

Package:wooden box

FAQ:

Q1: What's your guarantee?

A: All our products have 6 months guarantee after received goods, if any quality problem can contact us.

Q2: What's your delivery time ?

A: The common delivery time is 5-35 working days. The specific delivery time depends on the items and the quantity of your order.

Q3: What's your minimum order quantity?

A: MOQ is 150 kg.

Typical properties of high ductility copper foil

|

Classification

|

Unit |

Requirement |

Test Method |

| Foil Designation |

/ |

T |

H |

M |

1 |

2 |

3 |

IPC-4562A |

| Nominal thickness |

/ |

12um |

1/2 OZ |

3/4 OZ |

1

OZ

|

2

OZ

|

3

OZ

|

IPC-4562A |

| Area Weight |

g/㎡ |

107±4 |

153±5 |

228±8 |

285±10 |

580±15 |

860±20 |

IPC-TM-650

2.2.12.2

|

| Purity |

% |

≥99.8 |

IPC-TM-650

2.3.15

|

| Foil Profile |

Shiny side (Ra) |

սm |

≤0.4 |

≤0.4 |

≤0.4 |

≤0.4 |

≤0.4 |

≤0.4 |

IPC-TM-650

2.3.17

|

| Matte side(Rz) |

um |

≤6 |

≤8 |

≤10 |

≤10 |

≤15 |

≤20 |

| Tensile Strength |

R.T.(23℃)

|

Mpa |

≥150 |

≥150 |

≥235 |

≥280 |

≥280 |

≥280 |

IPC-TM-650

2.3.18

|

| Elongation |

R.T.(23℃)

|

% |

≥5 |

≥5 |

≥10 |

≥10 |

≥15 |

≥15 |

IPC-TM-650

2.3.18

|

| Subject |

Ω.g/㎡ |

≤0.170 |

≤0.166 |

≤0.162 |

≤0.162 |

≤0.162 |

≤0.162 |

IPC-TM-650

2.5.14

|

| Peel Strength(FR-4) |

N/mm |

≥1.0 |

≥1.3 |

≥1.6 |

≥1.6 |

≥2.1 |

≥2.1 |

IPC-TM-650

2.4.8

|

| Pinholes&porosity |

Number |

No |

IPC-TM-650

2.1.2

|

| Anti-oxidization |

R.T.(23℃) |

day |

180 |

/ |

| H.T.(200℃) |

Minutes |

60 |

/ |

Mesajınız 20-3.000 karakter arasında olmalıdır!

Mesajınız 20-3.000 karakter arasında olmalıdır! Lütfen emailinizi kontrol edin!

Lütfen emailinizi kontrol edin!  Mesajınız 20-3.000 karakter arasında olmalıdır!

Mesajınız 20-3.000 karakter arasında olmalıdır! Lütfen emailinizi kontrol edin!

Lütfen emailinizi kontrol edin!